Renovating your home with a patio or a new deck needs the best fasteners. However, there are a plethora of fastening tools available in the market. Thus, It is challenging to understand which one to use. Deck nails and screws are the two types of fasteners to secure your deck board. Both have distinct designs and applications. So, you need to know which one is best for decking and when and where to use them.

Deck nails are usually front-pointed metals that are non-corrosive. These are applicable for fastening deck boards. On the other hand, The threading fasteners known as deck screws are made particularly for decks. They have a head, a shank, and a cap. Deck screws are unique fasteners, only in the construction of decks.

Both fasteners are usable for fixing deck boards but have different pros and cons. I am here with the head-to-head comparison between deck nails and screws. So read on to dive into the topic and know which is best.

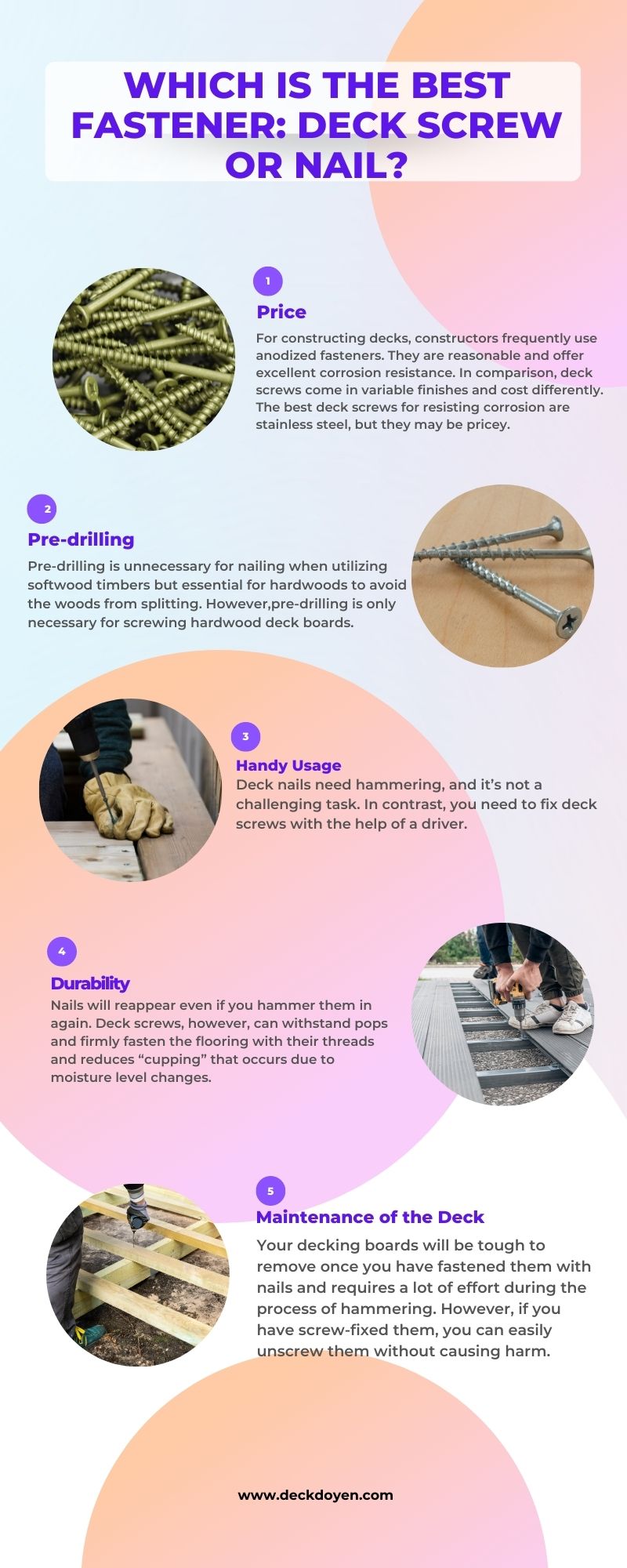

Which Is The Best Fastener: Deck Screw Or Nail?

Deck screws and nails are metal fasteners that are available in variable sizes. However, each has many benefits, so ensure you choose the correct fixing tools. Regardless, you may spend more or destroy the beauty of your deck surface. That’s why you need to look at them comparatively. It will help you decide which fastening hooks you want.

Price:

The cost is one of the main distinctions between utilizing nails and screws for wood decking. For constructing decks, constructors frequently use anodized fasteners. The prices of these nails are reasonable and offer excellent corrosion resistance. On the other hand, deck screws come in variable finishes and cost differently. The best deck screws for resisting corrosion are stainless steel, but they may be pricey. While galvanized screws are less expensive, they are less efficient at preventing rusting. The most common and affordable deck screws are with metal plating; galvanization. However, stainless steel screws are more costly.

Deck screws instead of deck nails result in increased labor expenditures. People often insert deck nails with a “coiled” air cannon and a head with a ring shank. It reduces labor expenses and spares a significant amount of time because installation is much quicker. In the end, deck nails are less expensive than deck screws, but most householders feel that screws are more costly since they last longer.

Also Read: Can Deck Screws Be Used For Framing?

Pre-Drilling:

Pre-drilling is unnecessary for nailing when utilizing softwood timbers, such as treated pine. Pre-drilling is essential for hardwoods like Merbau or Spotted Gum to avoid the woods from splitting. However,pre-drilling is only necessary for screwing hardwood deck boards. You don’t need to drill in softwoods because they don’t crack.

Easy To Use:

Deck nails need hammering, and it’s not a challenging task. In contrast, you need to fix deck screws with the help of a driver. That’s why it can be said that nailing is easy than screwing on wood planks. Removing a nail is tough. You can’t just put them out of your wood plank. However, in can screws, the threads allow handy removing of screws while rotating them with a screwdriver.

Durability:

Though screws have robust metallic construction, standard screws are sometimes fragile due to threading. The typical stainless steel screws are weak. Unlike nails, which curve and are hard to split in two, screws will crack quickly. Hence, nails are difficult to fasten but have durability against screws that are snappable.

Nail Vs. Screw For Exterior Pops And Clutching:

Deck designing with hardwood boards typically varies in size in response to weather and seasonal variations. Nails will ultimately be up If you use them for hardwood flooring. Thus, it will provide a safety risk for your deck. They will reappear even if you hammer them in again. With deck screws, however, this is not the case. They can withstand pops and firmly fasten the flooring with their threads.

Additionally, this improved fastening strength reduces “cupping.” When your decking boards cup, it means that as their moisture level changes, the edges rise. Your deck woods will then bend outward from the center as a result of it. Screws increase the strength and holding power of deck boards, reducing the likelihood that they may cup.

Upkeep Of The Deck:

Your decking boards will be tough to remove once you have fastened them with nails. However, if you have screw-fixed them, you can easily unscrew them without causing harm. Nail heads that protrude beyond the deck’s surface make it hard to sand it if you ever need to. Every nail must be “punched” further into the wood so the sander can easily travel over it. It can take a lot of time and might split your decking planks. On the other hand, decking screws may be easily separated (at the ends of the boards to reduce splitting) or driven deeper into the wood so that the sander can travel over them without being hampered.

Also Read: Can You Build A Deck Over An AC Unit? – Step By Step Guide

What Are The Characteristics Of The Best Deck Nails?

The variety of sizes and designs of nails is astounding. Stainless steel nails are ideal for decking because they give the highest resistance to corrosion and cause the least amount of discoloration in wood planks like cedar.

Compared to ordinary nails, stainless steel nails are much more costly. The most common nails for creating a deck are frequently double hot dipped galvanized nails since they are less expensive while offering high corrosion resistance.

It is essential to utilize double hot-dipped galvanized nails rather than standard galvanized nails since some galvanizing procedures only cover the nails with a thin layer of zinc, which can rust and vanish in a few decades.

Additionally, aluminum decking nails are considerably softer, more pliable, and more prone to corrosion when in touch with the copper preservatives of woods after pressure-treating. These factors lead us to advise against using aluminum deck nails while constructing a deck.

What Are The Benefits Of The Best Deck Screws?

Screws are available in a range of sizes and types, like nails. Although screws are almost as simple to drive as nails, they have greater gripping strength and a longer lifespan. Compared to nails, they are significantly simpler to take out without harming the wood. However, some individuals advise against using screws while building decks since their heads might collect a little water inside of them. For securing deck boards, screws are a far better option than nails since they won’t eventually crawl out of holes as nails do. In addition, screw threading aids in maintaining their attachment despite holding weight and touch for years.

Decking screws have coatings for corrosion resistance, self-sinking, tapered, and exceptionally sharp, setting them apart from other screws. Like stainless steel nails, stainless steel screws are the most costly but have the highest levels of corrosion resistance. However, utilizing stainless steel screws will save money by preventing a deteriorating deck or significant damage over time.

Also Read: How To Prepare The Ground Under Deck In 7 Steps?

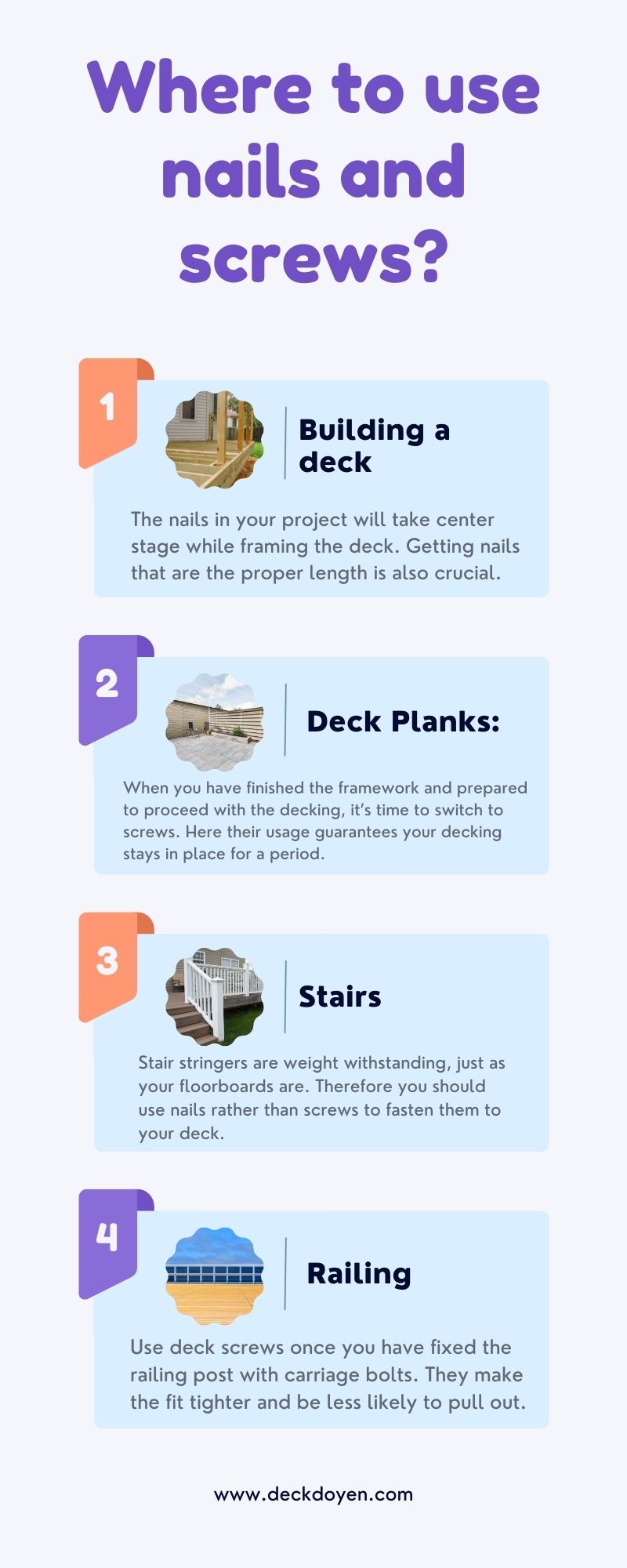

Where To Use Nails And Screws?

Well, now you know which one has more benefits. Now is the time to understand where to use them. Nails and screws are essential but in different places. So, let us dive into their uses:

Building a Deck:

The nails in your project will take center stage while framing the deck. You will need it for the framing that the manufacturer may have erected on top of the deck’s beams and posts unless you’ve chosen the structural screw option. You may use deck hardware as a reference to determine how many nails you need for each bracket. You will need six pointed fasteners to fasten if it has six holes.

Additionally, you’ll need 10-diameter metal nails and 16-diameter double-dipped galvanized nails that are 3-1/2 inches long for your joist hangers. Your hanger will be attached to the wall ledger using 16d nails, and it will reach the joist by driving 10d nails through the hanger’s side flange.

This process of building your deck requires a lot of effort. The choice for driving these nails in is the hand of a sled. If they don’t stop the task, it will swiftly convert one hand to plastic. The manufacturer made these hangers to accommodate the weight of your deck by using an adequate number of nails. Skip holes at your peril to the stability of your deck. Getting nails that are the proper length is also crucial.

For this project, you’ll need 3-1/2 inch-long 16d nails to ensure appropriate strength. Additionally, keep in mind that your deck will is facing the weather. Therefore, to avoid rust and potential calamity, be sure you’re utilizing double-dipped galvanized nails.

Also Read: Can You Build A Deck Over A Septic Tank? Step By Step Guide

Deck Planks:

When you have finished the framework and prepared to proceed with the decking, it’s time to switch to screws. Unless you want to use ring shank nails, resist the urge to grab for your pneumatic frame nailer at this point, as you’re utilizing screws to guarantee your decking stays in place for a period. To fasten your boards to the framework, you will need 3-1/2′′ deck screws, whether you choose conventional deck screws or structural screws. Make sure the screws you buy are rated for outdoor usage, just as you did with the nails.

Stairs:

Both screws and nails have a better application in the construction of deck steps. To use angle brackets to secure the stringers to the floor, you will need 1-1/2-inch hanger nails. Stair stringers are weight withstanding, just as your floorboards are. Therefore you should use nails rather than screws to fasten them to your deck. Understand that, unlike screws, it may bend but not shatter.

Railing:

As your deck project ends soon, you’re prepared to install the deck railings and balusters. It’s another task that is the best application of screws. The 2x4s will be fastened to the tops of the posts using 3.5-inch deck screws once you have fixed the railing post with carriage bolts. The balusters and top rail will be attached using the same deck screws. So, utilizing screws in this situation makes the fit tighter and less likely to pull out, leading to an unsafe railing. You don’t have to be concerned about the screws breaking because it doesn’t carry any weight.

Final Thought:

I would suggest using a mix of nails and screws when building a deck. In reality, if you examine numerous project specifications and construction rules for decks. You’ll discover that although elements of the structure need nails, others allow for the use of screws. The best method for installing the decking is with screws. They have superior fastener/tensile toughness and hold things flat better. Therefore, it prevents boards from popping up over time. However, you must use nails unless you select more costly screws for structural components like joists.

Also Read: How To Build A Deck Without Digging Holes? Step By Step Guide

Moreover, structural screws are recent versions of the fastener. Therefore they could not comply with historical building requirements, which could result in deck construction. Screws are necessary when utilizing hardwood, but you must always drill pilot holes first. Having screws is the best advantage for short-term holds because you can withdraw them without risking damage to the wood.

Frequently Asked Questions:

What Distinguishes Deck Screws From Wood Screws?

Deck screws have copper or stainless steel body and are more solid than wood screws. They work well outside due to their corrosion resistance. Contrarily, wood screws have a square head and a flanged.

What Should The Length Of screws For Deck Boards Be?

For deck boards, joists, and railings, deck screws measuring 25. inches and 3 inches often work well. For 4×4 posts, however, 6-inch deck screws are required.

Do Deck Screw Holes Need Filling?

You need to Fill up any holes left by incorrectly positioned screws and the tiny spaces above screws that you have countersunk into the deck to offer your deck boards a smooth and expert appearance.