Pressure-treated wood is a convenient and reliable option for a home’s outdoor space. Though it requires a lot less maintenance than untreated wood, you should never skip staining it.

We all know the benefits of staining wooden structures, but the process can sometimes get confusing, especially if you are unfamiliar. One common question most homeowners have is, what happens if you stain treated wood too early?

If you apply stain to pressure-treated wood too soon, the product will fail to penetrate the lumber fully. As an outcome, you won’t benefit from the protective qualities of stain. Thus, waiting for the treated wood to dry before staining to see the results is better.

Staining a deck made of treated wood adds an additional protective layer against damage. It also beautifies the outdoor structure; however, the right timing has a lot to do with witnessing these results. I am here today to guide you through all the queries related to staining treated lumber. Let’s read!

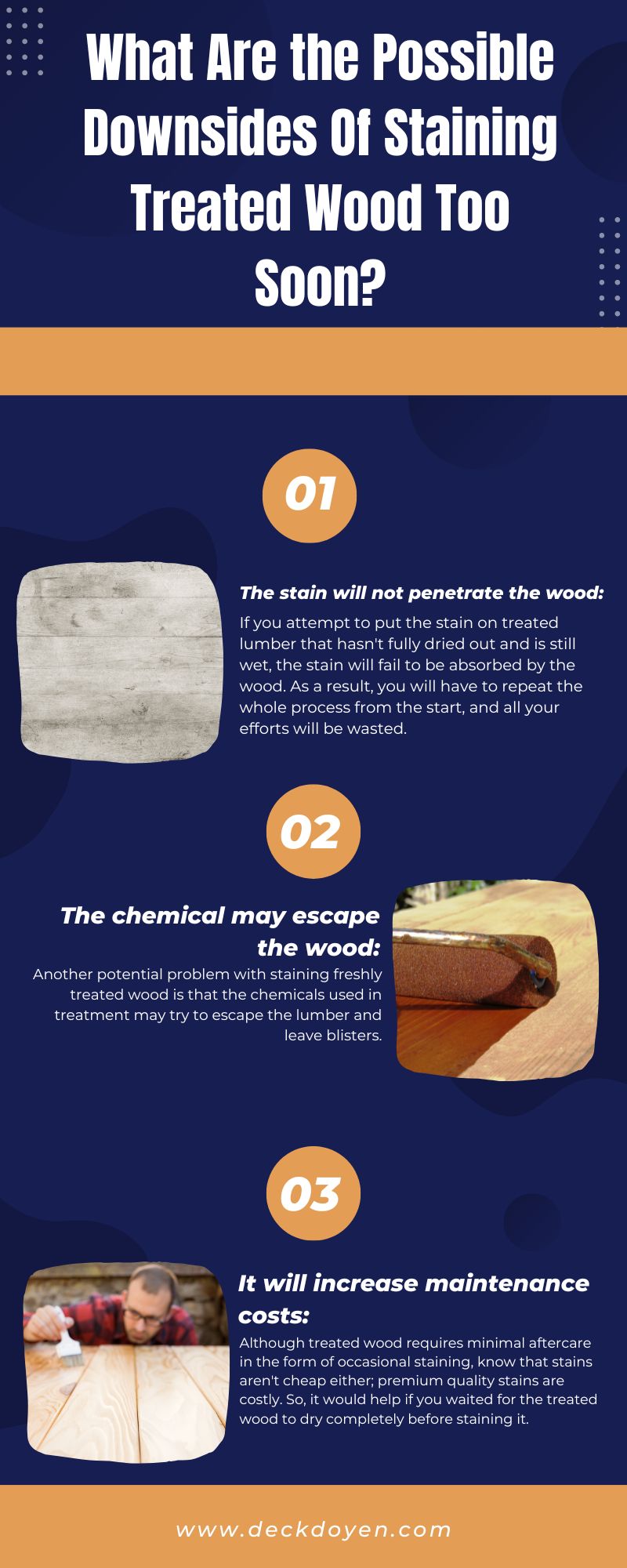

The Downside Of Staining Treated Wood Too Soon:

Pressure-treated wood is one of the ideal choices for constructing outdoor spaces. Compared to natural lumber, treated wood has a life span of over forty years, which is quite a lot. Although the chemical treatment protects the wood from weather damage, decay and breakage, it still requires occasional staining.

Such protective coating keep your outdoor space maintained, especially under humid conditions. However, the chemicals used for wood treatment require a drying time before starting the staining process.

If you stain the treated wood too soon, it might not yield the result you look for. Here’s what happens when you stain the pressure-treated lumber earlier:

The Stain Will Not Penetrate The Wood:

If you attempt to put the stain on treated lumber that hasn’t fully dried out and is still wet, the stain will fail to be absorbed by the wood. As a result, you will have to repeat the whole process from the start, and all your efforts will be wasted.

Also Read: How To Lay Decking On Grass? Step By Step Guide!

As you all know, stains need to penetrate the wood to give effective results, which is why the wood surface must be moisture-free.

The Chemical May Escape The Wood:

Another potential problem with staining freshly treated wood is that the chemicals used in treatment may try to escape the lumber and leave blisters. It means that your sealant won’t be that effective, and all the efforts you put into the process will go down the drain.

It Will Increase Maintenance Costs:

Installing an outdoor space, especially wooden, enhances the aesthetic value of your home, but they do come with a high price tag. Similarly, wood maintenance is yet another factor that can be hard on your pocket.

Although treated wood requires minimal aftercare in the form of occasional staining, know that stains aren’t cheap either; premium quality stains are costly, and you cannot risk wasting them by applying them to the wood too soon. So, it would help if you waited for the treated wood to dry completely before staining it.

How Much Should You Wait For Staining The Pressure Treated Wood?

Now that you have learned the importance of staining at the appropriate time, you might wonder when to start the process for your pressure-treated wood.

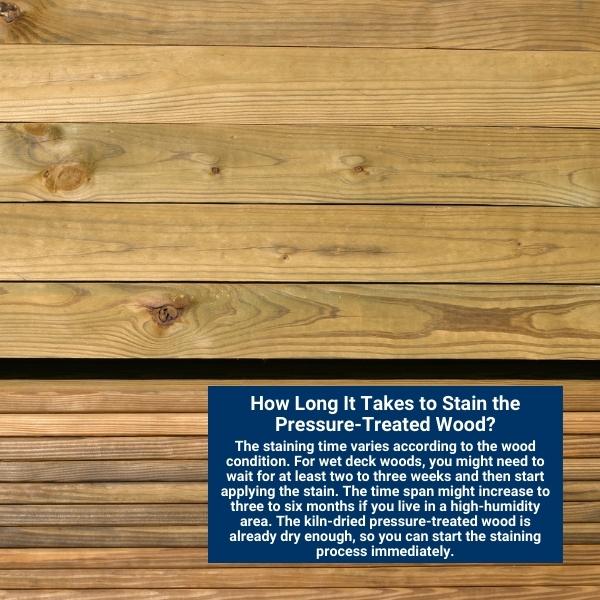

Different types of treated wood are available, so the waiting period before staining varies accordingly. Let’s take, for example, wet pressure-treated wood. This category of lumber is still wet when it’s finally sold at the wood stores. When you pick it up for your outdoor space, it feels damp to the touch.

So, if you got wet pressure-treated wood, you might need to wait for at least two to three weeks and then start applying the stain. The time span might increase to three to six months if you live in a high-humidity area.

The next category in line is kiln-dried pressure-treated wood. As they are already dry enough, you can start the staining process immediately. However, they are much more expensive than regular treated wood and often hard to find in the market.

How Do You Know The Treated Wood Is Ready To Stain?

One of the easiest ways to determine if the pressure-treated wood is ready for staining is by doing a quick test. All you need to do to check the dryness of the wooden surface is by sprinkling some water on it; this is known as the Sprinkle Test.

Wait for ten minutes, then observe carefully to see if the water beads up or not. If it does, this shows that the wood is still wet, and you need to wait a while before applying a stain coat. If the water soaks into the treated wood, it indicates that the lumber is dry enough, and it’s the perfect time to stain or paint.

Nonetheless, my advice is not to wait for too long for wood drying. With every passing day, the lumber without a protective coating is prone to ultraviolet light. These harmful UV rays can degrade the cell structure of the surface lumber fibers. Thus, it might reduce the effectiveness of the stain or preservative you intend to apply.

Also Read: Should A Deck Be Level Or Sloped? Detailed Answer!

What To Do If You Stained Way Too Soon?

If you accidentally stained your pressure-treated earlier than intended and the stain didn’t work properly, there are still ways to salvage it.

If you stained the wood with a lighter color, you must wait for the lumber to dry out completely and then reapply a darker stain coat. As the previous layer was lighter, it is almost impossible to notice any flaws, which is why the expert recommends starting with light stains.

Now, in the case, you went for a darker stain, or if the application didn’t turn out the way you wanted, you are left with no option but to remove the upper stain layer. You can use sandpaper or chemical stain strippers to get rid of it. Or, you might have to fully refinish the treated wood for a clean, fresh start.

Can You Delay The Staining Process For Long?

Yes, it is possible to delay the staining process a bit but remember, the more you delay, the higher the chances that your treated wood might be prone to damage, decay or insect attacks. It is why it is suggested to check if the wood is dry enough and then coat it with a protective layer of the stain as soon as possible.

Moreover, just as too much moisture isn’t ideal for staining, likewise, the absolute absence of it can also mess with stain adhering to the surface. The ideal moisture level for lumber should be around fifteen percent before staining. Or else, you might have to buy additional products for better stain application.

What Is The Best Stain To Use For Treated Wood?

With so many stain options, it can be not easy to decide which one to choose for your treated wood. The decision mostly depends upon what results you are looking for and what is on your checklist.

If you love the natural appearance of the wood and want to preserve it, I recommend going for a clear, transparent stain, or semi-transparent stains will also work fine. However, go for semi-transparent only if you are okay with changing your lumber colors, or you can get one that color matches the existing shade.

These work perfectly well for surfaces with warmer tones or those already tainted with preservatives. Also, if you are new to staining, transparent stains can be a safer option to start with. This way, you can easily transition towards darker stains, unlike from darker to lighter, which can be a hassle.

A lot of pressure treatments do possess water repellents as well. If this is the case with your treated lumber, you might need to opt for oil-based stains as they adhere to the surface much more effectively. It is highly useful for outdoor wooden structures in direct contact with the ground because the protective coat will last longer and prevent molds and mildew.

Here’s How You Should Prepare Treated Wood For Staining:

Pressure-treated wood is able to withstand rotting and insect attacks; however, its appearance can still suffer at the hands of dirt and debris over time. Thus, it is why it is necessary to prepare the treated wood surface well before stain application.

Make sure you thoroughly clean and sweep the outdoor area and remove every tiny piece of dirt and grit that can interfere with the smooth application of stain. Moreover, it would be even better to pressure wash or hose down the treated wood to eliminate all the underlying debris that would otherwise cause imperfections once the stain cures.

However, the process can get slightly complicated with older wooden structures because pressure washing won’t be enough. You will require special cleaners to get rid of stubborn stains and dirt accumulated over time. You can choose different cleaners, depending on the type of results you look for.

Conclusion:

Pressure-treated wood is the best choice for outdoor structures like decks due to its resistance to rots, damage and insects. But, the treated wood requires stain application to keep it well-protected from the changing weather conditions and to maintain its appearance.

Staining the lumber has endless benefits. However, the process must only be done when the wood is dry enough. If you stain it too soon, the product won’t penetrate the wood well, and you’ll have to repeat the whole process from scratch.

Also, good quality stains are costly, so it’s better to wait until the treated wood is fully dry before you start the coating process. A great way to guess if the treated lumber is ready to stain is by doing a quick sprinkle test. And, once the test shows a positive signal, better not delay the process for longer and stain the wood as soon as possible.

Also Read

The more you leave it unprotected, the higher the chances that the pressure-treated wood will suffer from damage and decay.

FAQs:

What Color Stain Looks Best On Pressure-Treated Wood?

It’s always best to stick with light-colored wood stains for newer decks constructed out of pressure-treated lumber, as you can easily upgrade to darker shades later. However, it isn’t easy to go back once you go dark with stain. Dark Ash is a very appealing, semi-transparent brown that looks gorgeous on rustic-treated wooden decks.

Is All Treated Wood The Same?

No, different lumbers are often treated accordingly, depending on the intent of use. For instance, wood meant for outdoor use may receive a different treatment than the one meant for the interior.

Similarly, wood targeted for use above-ground usually possesses a lot fewer preservatives in them. On the contrary, the lumber directly in contact with the ground generally has more preservatives for additional protection against rot and decay.