The high-quality cementing materials like deck mud and Concrete used for house building and repair might cause a little distress for DIYers. Though people use the names interchangeably, both are unlike each other and have distinct functions and compositions. That’s why most of you might want to know which one is best to use, where, and how.

Deck mud, also known as dry pack mortar, is a cementing material that is a mixture of sand cement and water. It is used for minor repair, filling of spots, shower bed formation, and the fixations of tiles and brick. However, Concrete is a solid material having sand, cement water, and rock chippings. It is the actual building material for wall foundations and masonry.

Concrete and deck mud have similar compositions but completely distinct properties and usability. Thus, it is not suitable to substitute them as it may compromise the strength of the building.

Therefore, I have compiled all the information about concrete and deck mud. So, keep reading the article to know; what makes Concrete different from deck mud.

Why Is Deck Mud Different From Concrete?

House building, repairs, and apartment construction need sturdy and durable material to stand tall for years. It should be able to withstand all weather conditions. Therefore, you must use the correct material in the right place. Dry pack mortar and Concrete are two distinct building materials that are usually confused with each.

If you are a DIYer or planning to build your new house, you must not swap the two materials. It can mess up your house foundation. Concrete is a suitable building material for a solid foundation against deck mud which works like glue and supports bricks and tiles. Hence, there are so many characteristics that differentiate them. Let’s get to know it.

Components:

Both materials have a similar composition: sand, cement, and water. However, the Concrete includes aggregates to make it firm and solid. These aggregates are either rock chippings or gravel to strengthen the Concrete for the solid structuring of houses. Besides, dry mortar must have lesser water content than Concrete. Thus, it would be best to mix in the right consistency for better functionality. As a result, Concrete has a structure founding application, and mortar is suitable for brick solidifying.

Also Read: Oil Vs Water-Based Deck Stain: Which Is Better And Why?

Strength:

Gravels and rock chips bolster the concrete blend. Since Concrete has more solid aggregating materials than deck mud, its usage strengthens the building up to 10 fold. Besides, these additional components also speed up the drying duration of your concrete mix. Thus, never replace Concrete from deck mud for wall foundations as it will weaken your wall.

Consistency:

The water to cement ratio of your cementing material is essential as It may affect the application. Though the concrete mixture has more water content, it gets firm after drying. In contrast, the consistency of deck mud is thicker, yet it’s not that tough. You must take care of the water to cement ratio because the wrong viscosity may harden your brick bonding or tile adhesion. However, for Concrete, you don’t need to worry about its consistency.

Durability:

Deck mud is famous for its bonding and sticking ability rather than stability and durability. Therefore, you must replenish it twice in four decades, or your tiles and blocks might start to fall apart. However, Concrete has a strong bonding and doesn’t have to tolerate environmental corrosion to last centuries. Besides, materials like plasticizers in the blend also help the longevity of the concrete structures.

Also Read: Best Temperature Ranges For Staining Deck

Usage:

Using deck mud for building supportive structures is not recommended because it does not have relative durability to hold weight. Therefore, experts consider Concrete better than deck mud because it makes the buildings strong, lasting, and withstanding. In contrast, concrete use for floor beds, shower beds, and tile adhesion is a bad idea. The gravel and rock chips in the concrete mixture will not make your surface smooth. Moreover, it will not be able to stick the tiles on the floor or adhere to two bricks to hold the wall due to the aggregates.

Cost:

Deck mud costs less than Concrete but lasts only 20 years. On the contrary, Concrete is a little expensive but does not need repair for even a century. Since you will have to replenish deck mud after 25 years, your cost will be double. So, it is better to invest one time by using Concrete. It will help you save in the long run and keep your house withstand extreme conditions. Hence, Concrete is better than deck mud in terms of price and durability.

What Should Be The Proportion Of Components In Deck Mud And Concrete?

Pre-mixed packs of both deck mud and Concrete are available in the market. Yet, for working on large contracts, you must know the right proportion of sand, cement, and other components.

Usually, contractors mix four parts of fine sand into one of cement for minor repairs. Still, if you want some stability, experts recommend adding cement and sand in the ratio of one to three, five, or six. It is water that you need to add carefully. The requirement of water depends on the moisture level of your sand. If your sand is too dry, put in more water. However, you must ensure that it’s neither too dry nor watery.

Concrete mix preparation depends on the level of strength you want to achieve. For sturdy foundations of houses, mix 1 part of cement into 3 part sand and 6 part aggregate. For other uses, experts suggest mixing cement sand and gravel in the ratio of 1:2:4. It is enough to keep the structure last for more periods. However, dams and water bridges may need more strength, so you can add plasticizers and metal aggregates to make them durable and enduring.

Also Read: When To Stain A New Deck Pressure Treated?

How to Use Deck Mud And Concrete?

The two cementing materials require the following steps for their application:

Application Of Deck Mud:

Firstly, ensure all surfaces are structurally sound, clean, and free of dirt, filth, dust, cementation, waxes, lubricant, curing agents, cleansers, surface coatings, and adhesive before applying anything to them. You must remove anything that might prevent a good connection, such as residues or layers of gypsum. Secondly, prepare a smooth surface. You can also use mechanical techniques like sanding, scraping, or utilizing abrasives to prepare for smooth surfacing. Then dampen the surface, but don’t let the water sit there. Lastly, apply the deck mixture to the surface. The suitable temperature range is between 45°F (7.2°C) to 85°F (29.4°C) for better results.

Drying And Curing:

Let newly imposed deck mud dry for at least a day. Drying time is not constant depending on substrate porosity, environment, and project circumstances. However, it must not exceed 24 hours at utmost humid temperature levels of 70°F (21°C) and 55 percent humidity. After 28 days, the material gets cured naturally. These conditions will keep your structures crack-free for decades.

Deck mud requires sufficient time and suitable environmental conditions for drying and curing. If it doesn’t get the time to dry and cure, It may get cracks after a few days. In that case, You can also use a Pre-Mixed Concrete Patch Amazon Product (Affiliate Link) to fill cracks and holes in concrete surfaces. It is easy to apply and dries quickly, making it ideal for quick repairs.

That’s why I have authored the step-by-step process of drying and curing deck mud. Moreover, I have also mentioned a suitable temperature condition for your convenience.

Application Of Concrete:

Concrete application is not as straightforward as deck mud. It is a challenging task. Firstly you need to clear the surface as you do for the deck mud and then spread the concrete mixture with the help of a shovel. Then level and smooth the surface using Amazon cement-based smoothing product Ardex Feather Finish (Affiliate Link) with the help of darby with slight pressure to ingrain the aggregate. Let the excess water disappear, and then neat the edges. After that, remove all cracks and finish the joints. Lastly, use a towel or street Fresno to give your surface an attractive finish. Let it air dry for at least a day in the same temperature conditions as deck mud.

Also Read: Can You Put A Gas Fire Pit On A Deck? Best Method Revealed!

What Are The Different Uses Of Deck Mud And Concrete:

Deck mud and Concrete have different applications, considering their stability, longevity, and composition of deck mud and Concrete. Hence, each material is best suitable for entirely distinct usage. Still, it is possible that your house building requires both deck mud and Concrete. So let’s compare the usability of concrete and deck mud.

Deck mud is usable for creating regular thick mortar beds, surfacing concrete grounds, and forming shower bases. Besides, it is also workable for cementing brick walls and glueing tile on the floors. Contractors also apply deck mud over waterproofing and joining layers. Hence, it is an essential material for both residential and commercial constructions.

Concrete is appropriate for wall foundations, dam construction, and building framework for profound structure and stability. It is also suitable for building pathways, roads, sewers, and house fences. Besides, Concrete is a cost-effective material for building dams, ditches, piers, and abutments. Hence, it is a building material that has necessary usage around the globe.

Also Read: Deck VS Curb Mounted Skylight: Differences, Costs, Pros And Cons

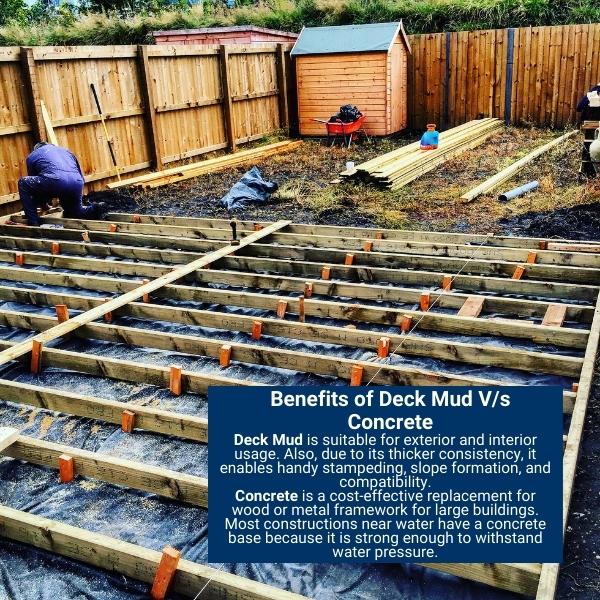

What Are The Benefits Of Deck Mud Vs. Concrete:

As both building materials have different uses, they also have distinct benefits. Thus, you neither deny the importance of deck mud and Concrete nor use them interchangeably. So here are the comparative advantages of mortar and Concrete.

The foremost benefit of deck mud is that it’s suitable for exterior and interior usage. Besides, due to its thicker consistency, it enables handy stampeding, slope formation, and compatibility. You also don’t have to mix the sand and cement at the construction site. Its smooth consistency also makes it beneficial for time-taking commercial building contracts.

Concrete also has several benefits; it is a cost-effective replacement for wood or metal framework for large buildings. It also keeps your walls sturdy and cracks free for years. Most constructions near water have a concrete base because it is strong enough to withstand water pressure. That’s why Concrete is also preferable for dams and bridge construction. Besides, one can also stamp it to design reflective floors and form small sculptures and fountains.

Conclusion:

Concrete and deck mud possess different properties. Contractors can’t ignore their vitality at construction sites as every building task like commercial and residential house building, renovation, and infrastructure building require both materials. Yet, most people don’t know the difference between two building materials and make the mistake of replacing Concrete with deck mud or vice versa. As a result, they lose money, time, and energy while compromising the strength of their project.

Also Read: Can You Build A Deck Over A Septic Tank? Step By Step Guide

So, even if you are a DIYer or contractor, understand that deck mud is a cementing material while Concrete is a construction mold. Deck mud is not sturdy yet has remarkable adhesive qualities to keep your brick, stones, and tiles fixed for years. It is not for filling small gaps and holes. On the contrary, Concrete is the material for constructing structures and foundations. That’s why it needs to be durable, stable, lasting, and tough enough to endure weather conditions and pressure. So, never exchange them.

FAQs

What Are The Two Different Types Of Concrete?

Any structure having ground or flat surface support is plain Concrete. For instance, walkways, driveways, slabs, and spread footings are plain concreting because their base is flat on the ground. Moreover, contractors include steel into plain Concrete to make it withstand variable temperatures. On the other hand, structural concretes with support points. They must be capable of holding support weight, such as concrete slabs, beams, and pilings.

Can I Use Deck Mud For Building The Foundation?

No, It would not be best to use deck mud for constructing the foundation of any building. Deck mud is inappropriate for building supportive structures because it is an adhesive material. You should use Concrete for the foundation because it has stability, durability, and lasting quality to withstand extreme pressure and hold loads. Additionally, deck mud in the house foundation may add to the cost of repair and reconstruction after a decade.

What Is The Appropriate Method Of Storing Deck Mud?

It would be best to have it in a cool and dry place. The suitable temperature range is 40°F (4°C) to 90°F (32°C) to keep it in better condition. You should keep it away from direct contact with the ground or Concrete. Moreover, one must place it in shady places away from bright sunlight to guard against weather and other harm.