Pressure-treated wood can only protect from early decay and pest infestations but cannot keep humidity from penetrating the wood. Water can soak through the planks of a deck that gets repeatedly revealed to rain and induce it to expand. Later the wood starts drying in the air.

This ongoing sequence of bulging and contracting will result in the deck splitting, breaking, and distorting over time. Therefore, it’s necessary to opt for sealing the pressure-treated wood, but how exactly and perfectly can one achieve this process?

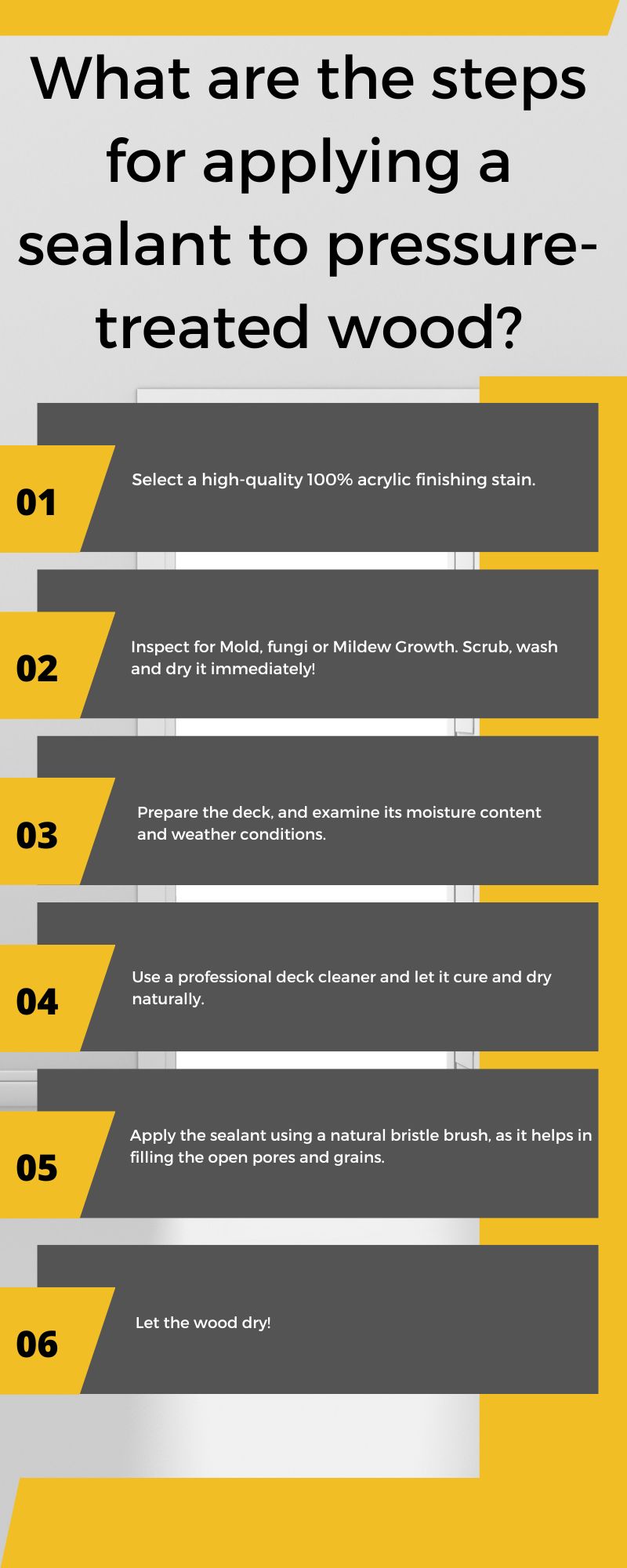

You can seal the pressure-treated deck wood by using a high-quality sealant. Inspect for mold or other residues and clean the deck thoroughly with a power wash. Now apply the sealant over your pressure-treated lumber and let it dry for at least 3 days. It’s best to examine the weather condition before applying further coats for trusted results.

The recipe for sealing pressure-treated wood is simple, but if you don’t do it at the right season using the correct methodology, it will not give the desired result. Additionally, not taking the necessary precautions will also disappoint you. So, let’s understand how to seal the pressure-treated wood in detail.

What Is The Right Method To Seal Pressure-Treated Wood:

Pressure-treated wood is extremely challenging to dye and seal than other deck woods. That’s why many suppliers recommend not doing it. However, most varieties of pressure-treated lumber need perfect sealing and preservation; here’s how you can seal it correctly to ensure that the sealant clings to the deck surface.

Select The Stain:

Select between a translucent stain or a clear sealant. The finest UV coverage comes from strong stains and dyes, but they typically don’t react effectively to the chemical coatings of treated wood. These materials deteriorate and erode randomly, and your deck will need repainting soon.

Inspect For Mold, Fungus, Or Mildew Growth:

Before sealing the wood, inspect it for mold. Mold growth is widespread on pressure-treated wood since the agents used to cure it retain water. Scrub the fungus away with a mixture of 1/2 cup of household bleach for each liter of water. Then thoroughly wash the wood and let it dry.

Prepare Your Wooden Deck:

Before you begin, ensure that your deck wood is debris-free. For coating an old wooden deck, you may have to power-wash the deck to clear any accumulated grime.

Clean Deck Surface:

Use a professional deck cleaner, and as per the product’s guidelines, clean any deck areas you will seal. Most solutions work better after a thorough cleaning with a scrub pad. Let the pressure-treated wood cure for a minimum of 48 to 72 hours after properly rinsing it.

Apply The Sealant:

Use a brush, sponge roller, or spray to spread the sealant over the deck. A lawn spray bottle is a simple and efficient way to apply a clear sealant. Spray semi-transparent stain using pressurized air or a portable airless spray. As you proceed, wipe off any puddles of extra sealant. Apply the sealant into joints and max 4 boards in length with a single stroke to avoid overlapping effects.

Let It Dry:

Allow it to dry fully. Most pressure-treated wood sealers need 1 to 2 days to dry. For example, PT lumber needs at least three days to lose moisture completely. Therefore, ensure no rain forecast in the next three days. After that, you can apply the next coat if needed. You can read my article about How Do I Know If My Deck Is Dry Enough To Stain?

Tips For Better Results:

Use a transparent product with UV protection in sunny places. Oil-based sealers are more effective and last better than water-based ones. Water-based sealers cling to the top, but oil-based sealers soak swiftly into the wood.

It’s a common misconception that wood must leave untreated for a few months before sealing. It is false and exposes the deck to harm. Allow new pressure-treated timber to cure for 30 days without sealing. Check the label to see if you use certain products for new PT lumber right away, like redwood and cedar.

What Is The Best Time To Apply Sealant On Pressure Treated Wood:

Even though you understand why deck sealing is crucial, your initial reaction will likely do it immediately. However, whenever it comes to improving the effectiveness of your deck, time is crucial. If you apply a transparent sealer, the wood will ultimately become gray, though it will do so more gradually than untreated wood.

A newly constructed deck of pressured wood must cure completely before sealant application. The drying periods differ depending on the wood and the environment. Kiln-dried timber requires the least amount of time to dry, whereas certain varieties of wood require two to three months before sealing. The substances used to cure made the wood hydrated, and according to the temperature, drying time might range between a few days to several months.

How To Maintain Your Deck?

Maintaining Pressure Treated wooden deck is the most effective technique for retaining its esthetic appearance and durability for a longer period. Once a year, clean your deck and reseal it with a fresh layer of sealer to preserve the wood from deteriorating and breaking. Remember that PT woods are a beautiful, cost-effective, and long-lasting decking material with appropriate care.

Final Words:

Sealing pressure-treated wood is crucial to keep it preserved. However, it would be best if you let the new deck dry and clean before sealing it. Additionally, choose the right sealant and the right time to seal it. I am sure now you know how to seal pressure-treated wood, and you will do it yearly to preserve your deck wood.

FAQ:

How Long Will Pressure-Treated Wood Endure If Left Unfinished?

PT timber lasts long, whether used solely for construction or for deck flooring. Lack of care maintenance exposes pressure-treated timber to frost-defrost and wet-dry phases, so it will only last around nine years. The same decking will survive for 45 years if properly maintained and treated.

What Are The Qualities Of The Best Sealant?

I suggest a branded business sealant with a 100% acrylic finishing recipe for pressure-treated planks. With its easy application, you can do it in a single day and get the ultimate result. The UV-resistant nature increases the esthetic beauty and longevity of the deck.