I understand how it feels to have simply built a deck on your own or with the help of a contractor. Even if it looks fantastic, you are prepared to paint or stain those unsightly, green-tinted frames. Therefore, it’s best you figure out how long you should wait before staining pressure-treated wood.

You should give the pressure-treated wood anywhere from 4 weeks to 6 months to dry before staining it. However, this period may vary from a few weeks to several months based on factors like the kind of treated wood utilized, the air humidity, and the temperature.

I can guarantee that your stained pressure-treated wood will be in great condition for your anticipated project by following the instructions provided below: whether it be a fence, balcony, or deck.

How Long Should A Pressure-Treated Wood Be Left Unstained?

It could take 2 to 3 days to stain your deck after it has been built, depending on the kind of wood used, the temperature, and the amount of moisture in the wood. It is more likely to stain after it is finished if you are using premium-treated wood. Wet-treated wood, however, can take several weeks to stain.

Applying a series of tests or determining the wood’s moisture content is the best course of action. It is ready to stain if the ranges between 6% and 25%. However, it’s preferable to wait for one if the humidity level in your location is higher than 55%.

Factors That Affect How Long Pressure-Treated Wood Takes To Dry

Each variety of wood has a different waiting period. Why? The amount of time treated wood takes to dry depends on several variables. You may have to wait anywhere between 4 weeks and 6 months longer for them.

Also Read: Kreg Deck Jig Vs Camo? Which One To Use And Where?

Let’s examine these elements and how to choose the appropriate waiting period.

Used Wood Type:

Would you stain your products as soon as they are finished? The type of pressure-treated wood you are using makes a big difference. Professionals frequently employ two primary types of wood for outside projects:

- Moist-treated Wood: A lot of chemicals are applied under constant pressure when treating this kind of wood. Consequently, moisture becomes trapped inside the wood and takes some time to dry out. It may take 2 to 3 weeks for this wood lumber to get dry completely before it can be utilized in your projects. To keep it moisture-free, though, you should wait six months to a year in tropical regions like Florida. Long enough!

- Kiln-dried Pressure-treated Wood: This particular kind of treated wood has previously been dried out in a kiln. Thus, drying would proceed more quickly under optimal climatic conditions, like temperature and moisture, perhaps two to three days. After purchasing, it is stronger and prepared for staining. However, it is overpriced and largely inaccessible for purchase in retail stores. Regardless of the benefits, not many people use it.

Which Type Of Stain Do You Want To Use:

Before you begin, it is crucial to plan the type of stain you will use. For treated wood, two stains variations are offered.

- Water-based Formula

- Oil-based Formula

Water-based stains can be easily removed and are no longer useful. Totally moisture-free treated wood is required for this staining kind as the stain contains water. A composition based on oil is more resilient to the elements. Such stains should be applied to external constructions to achieve long-lasting benefits. But it also relies on your financial situation.

Applying inexpensive stains is possible if you use the water-based method. However, you might need to use it multiple times. Professionals frequently employ base primer coatings to extend the lifespan of aqueous stains.

The Temperature In Your Neighborhood:

The weather is another significant factor in deciding how long treated wood takes to dry. You must wait additional weeks to stain your wood if you reside in one of the coldest regions, such as Canada, where the winters are too lengthy. It can take two weeks or a whole month. However, keep an eye on the wood by performing frequent water tests.

Treated wood is expected to dry rapidly in dry, hot climates with easy access to sunlight all year round. In Asian nations where the summertime lasts for too long—roughly six months—the dry season will be too brief. It would take longer in tropical locations than you anticipated because heavy rains will make the air more humid. Therefore, it can take longer than four weeks.

Level Of Moisture In Your Region:

It follows a double-checked process. The treated wood itself or the surrounding air may both contain moisture. No more than 55% humidity should be present. According to the scenario, the likelihood of wood becoming damaged will rise if moisture levels rise beyond 55%. Floorboards and outside wooden frames will swell.

But based on the moisture outdoors as well, the moisture content within the wood should range from 8% to 25%. You may need to wait longer before beginning staining if the moisture level rises over this point. Most often, it occurs in tropical regions. The best course of action is to introduce wood to sunshine as frequently as possible. Moisture will routinely evaporate in this way.

Also Read: Deck vs Interlock: Which One To Use And Where?

Is My Deck Protected If I Stain It?

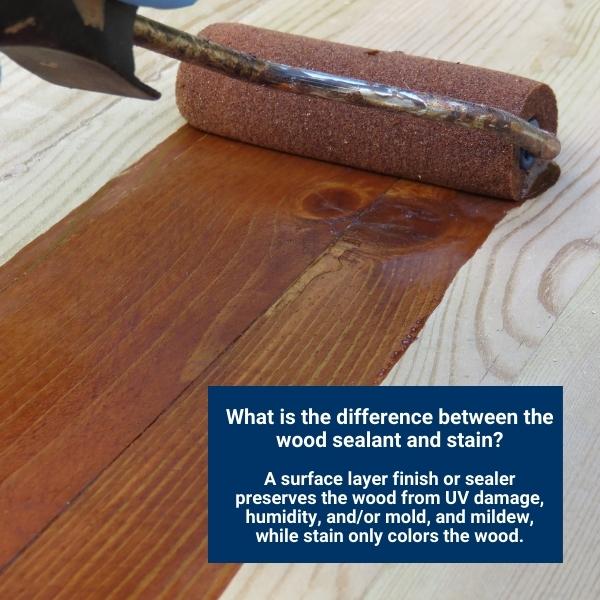

Most people mistake wood sealant for stain. A surface layer finish or sealer preserves the wood from UV damage, humidity, and/or mold, and mildew, while stain only colors the wood.

Many more recent formulations come with both a stain and a sealant. You can purchase each separately, but keep in mind that if you simply stain your deck without applying a protective coating sealer, the stain will fade, and the wood won’t be protected from the outdoors.

Conclusion

Finally, the only choice is to wait before staining pressure-treated wood, depending upon the conditions mentioned. Examine the wood’s water content first to improve the appearance of your woodworking products. Wet wood is less durable and stronger than dry wood. Pick carefully! Even though kiln-dried coated wood is expensive, it is still worth the expense. Therefore, I advise against using wet wood.

Also Read: Can You Install Composite Decking In The Winter

The owner can also add character and flair to the landscape by staining a pressure-treated wood fence or deck in addition to providing further safety from rotting and deterioration. Simply follow the above instructions, and you will be on your approach to a lawn that is even more magnificent!

FAQs

What Tends To Happen If Pressure-Treated Wood Is Stained Too Soon?

Early staining can cause the stain not to be soaked by the wood, resulting in a spotty and unsuccessful improvement for your deck. Before attempting to apply stain, be certain the wood has completely lost all of the extra moisture. Verify the wood’s ability to absorb water to determine that the drying process has been completed. The wood is prepared for staining once it has dried.

Is Stain Required For Pressure Treated Wood?

It is not necessary to stain pressure-treated wood. However, staining is an excellent choice if you are unhappy with how it appears and want to change color. It offers you a lovely natural appearance and provides an additional degree of security. Based on the treatment you use, staining pressure-treated wood can effectively deter exterior splitting and keep humidity out for longer. Therefore, even though it is not necessary, it is still worthwhile.